PRODUCTS

Ultra-high Pressure WaterJet Cleaning System-Diesel Driven

Keyword:

Ultra-high Pressure WaterJet Cleaning System-Diesel Driven

Inquiry

Product description

Product features

Compared with traditional manual and mechanical cleaning, chemical cleaning, biological cleaning and other cleaning methods, ultra-high pressure waterjet cleaning has the following advantages

1. The pressure and flow rate of waterjet can be adjusted conveniently, so that the substrate of the cleaned object will not be damaged;

2. Ultra-high pressure waterjet cleaning belongs to physical cleaning, which has no harmful substance discharge and environmental pollution, and will not cause secondary pollution;

3. Various changes of nozzle can clean objects with complex shapes and structures, and can carry out cleaning operations in places with narrow space or harsh environment;

4. Ultra-high pressure waterjet cleaning is fast and thorough. For example, the cleaning rate of heat exchanger is over 95%, and the descaling rate of boiler is over 95%;

5. The cleaning cost is low, only about 1/3 of that of chemical cleaning, which belongs to energy-saving equipment.

Technical parameters

|

Equipment model |

10015-C |

13530-C |

27030-C |

|

Maximum pressure (Mpa) |

138 |

275 |

275 |

|

Maximum flow rate (L/min) |

28 |

20 |

38 |

|

Power (KW) |

75 |

100 |

200 |

|

Length, width and height (mm) |

2400×1550×1780 |

2400×1550×1780 |

2810×1750×1891 |

The ultra-high pressure water cleaning products manufactured by Dardi are widely used in automobile manufacturing, petroleum, chemical industry, electronics, shipbuilding, textile, steel & iron, bridge and road, national defense, and other fields, and have won widespread praise and trust from customers.

·In the petrochemical industry, tanks, containers, and some pipelines must be cleaned for maintenance. The reactors, autoclaves, containers with agitator, and tanks shall be free of residue and sediment.

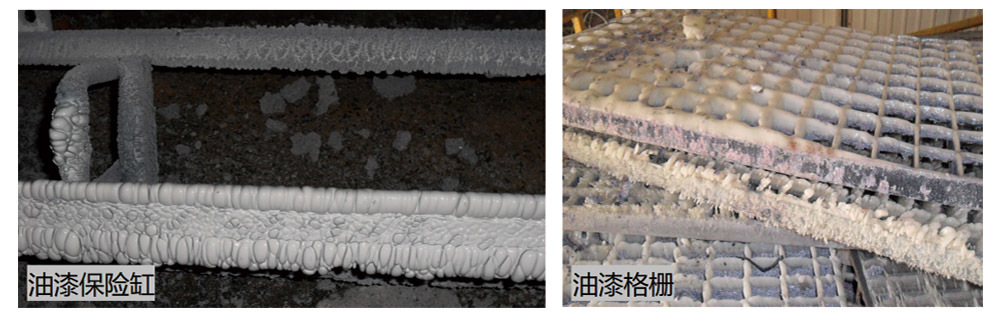

·In ship building, ultra-high pressure water cleaning is used to remove rust generated in steel pretreatment and coating engineering; the burned primer, welding slag and sediment produced in the welding process; and the melted rust, dirt, and a large amount of sea salt deposited on the cross sections of the prefabricated hull.

In ship maintenance, ultra-high pressure water cleaning is used to remove the marine organisms on, cabin or propeller; to strip off the rust and coating on the surface of cabin, ballast tank, and fuel tank; and to remove the paint coating above and below the hull waterline, etc.

·In the rubber removal of airport runway, high-pressure water cleaning is used to eliminating the low friction coefficient arising from the thick rubber layer of the airport runway, which can affect the braking performance of the aircrafts.

In the urban construction, high-pressure water cleaning is used to remove the zebra crossings quickly.

·In machinery manufacturing, ultra-high pressure water cleaning is used for cleaning of the precision parts such as deburring of engine cylinder head and cleaning of plating.

In production system, cleaning can not only guarantee the cleaning effect, but also guarantee the safety of the operation process. All types of dirt such as cutting, grease, oil and emulsion must be cleaned off quickly and effectively, so as to guarantee the continuity and safety of the production process.

·In automobile manufacturing, high-pressure water cleaning and saturated steam cleaning are used to clean off scrap iron, welding slag, anti-rust oil, and other stains on the surface of the workpiece in the welding workshop, so as to improve the paint adhesion ability and the paint spraying quality.

·In destruction and demolition of roads and bridges, high-pressure water jet is used to remove the deterioration of concrete caused by corrosion and for other reasons. Without affecting the original structure of the concrete structure, the partial deterioration of concrete is removed and no vibration is generated, so that the original components are repaired and become more firm and safe, so as to save a lot of investment and maintenance costs, and extend the service life of the concrete structure.